Elevate Your Projects with Our Fused Silica Wafers Low Coefficient of Thermal Expansion

Datos del producto:

| Lugar de origen: | PORCELANA |

| Nombre de la marca: | CQT |

| Certificación: | ISO:9001, ISO:14001 |

| Número de modelo: | Silicona fundida, cuarzo fundido |

Pago y Envío Términos:

| Cantidad de orden mínima: | 10 pcs |

|---|---|

| Precio: | Negociable |

| Detalles de empaquetado: | El paquete del tarro del casete, vacío selló |

| Tiempo de entrega: | 1-4 semanas |

| Condiciones de pago: | T/T |

| Capacidad de la fuente: | 20000 PC/mes |

|

Información detallada |

|||

| Material: | Silicona fundida, cuarzo fundido | Marca: | JGS1 JGS2 JGS3 |

|---|---|---|---|

| Diámetro: | 50.8 mm,76.2 mm, 100 mm, 150 mm, 200 mm. ¿Qué es eso? | Espesor: | 200um 350um, 500um, 1000um |

| El valor de las emisiones de gases de efecto invernadero es el valor de las emisiones de gases de ef: | < 2 μm | El valor de las emisiones de gases de efecto invernadero es el valor de las emisiones de gases de ef: | ≥ 95% ((5 mm*5 mm) |

| Superficie: | DSP SSP | Solicitud: | Semiconductor, mems |

| Resaltar: | fused silica wafers low thermal expansion,piezoelectric wafer with thermal stability,silica wafers for precision projects |

||

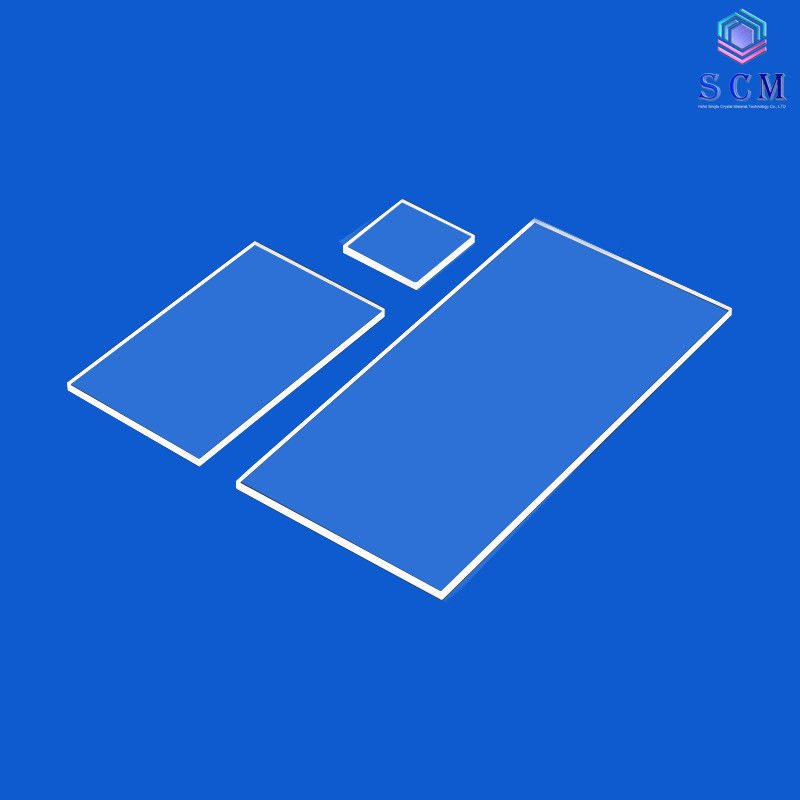

Descripción de producto

Elevate Your Projects with Our Fused Silica Wafers Low Coefficient of Thermal Expansion

Transform your high-tech applications with our premium Fused Silica Wafers, engineered from ultra-high-purity synthetic silica (SiO₂) to deliver exceptional optical clarity, thermal stability, and chemical resistance. Ideal for laser systems, photomasks, semiconductor lithography, and precision optics, these wafers boast a transmission rate exceeding 99% across UV, visible, and near-IR spectra, ensuring minimal signal loss and distortion.

Crafted with advanced flame hydrolysis or CVD processes, our Fused Silica Wafers feature ultra-low birefringence, sub-nanometer surface roughness (Ra < 0.5 nm), and precise thickness control, meeting stringent demands for flatness and parallelism. Their high laser damage threshold and resistance to thermal shock make them indispensable for high-power applications, while their inertness to acids and alkalis guarantees longevity in harsh environments.

Available in customizable diameters (2"–8"), thicknesses, and surface finishes, our wafers seamlessly integrate into R&D and production workflows. Backed by ISO-certified manufacturing and rigorous quality testing, they ensure consistency, reliability, and cost-efficiency at scale.

Elevate your optical performance. Choose our Fused Silica Wafers for unmatched precision and durability. Contact us today to unlock innovation in your applications.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

FAQs:

- Q: What are the products you mainly work on?

A: We look at ourselves as the piezo wafer specialist. We are the very first to work with Single Crystal Quartz in China about 30 years ago. Then gradually we step in the field of LiNbO3, LiTaO3, Quartz glass, LGS, CTGS etc. Especially, if you are looking for a piezo quartz supplier, we are the ultimate choice! We export millions of quartz blanks each year because we master the AT, SC and IT cuts with superior angle precision.

- Q: Can you accept product customization?

A: Yes, of course. We can fabricate as per your request. In addition, we are so experienced with piezo wafers that we can provide you relevant suggestions if you are not 100% sure about your choice. Besides, we do have some standard wafers in stock, please check with us.

- Q: Can you deliver the goods via our courier agent?

A: Yes, we would suggest you go with the courier agent you are most familiar with (DHL, FedEX, UPS etc.). We can ship via your account. And, of course, we will pack the products safely in acceptable size to help you save the shipping cost. If you need us to take care of the freight, it’s also not a problem. We also have good discount with the international courier companies.

- Q: How can you guarantee we get what we want safely?

A: The wafer products are fragile and sometimes expensive. The last thing, as the manufacturer, we want to see is the products we make were damaged during courier. As a result, we will pack the wafers adequately and put them in a proper carton filled with buffer sponge. However, accidents are inevitable sometimes. So, please follow the “Acceptance check” steps shown in the drawings below. If the unwanted happened, we will either give the replenishment or refund if you follow the checking steps.

- Q: Can we visit your factory?

A: Sure. Factory inspection is important for large quantity purchase and long-term cooperation. Face to face discussion is what we mostly confident with. During the past years, big names around the world have witnessed our progress in factory build-up. These days, due to the Covid-19 pandemic, we also had the experience of videoconferencing with global buyers.

Acceptance Check

- The product is fragile. We have adequately packed it and labeled it fragile. We deliver through excellent domestic and international express companies to ensure transportation quality.

- After receiving the goods, please handle with care and check whether the outer carton is in good condition. Carefully open the outer carton and check whether the packing boxes are in alignment. Take a picture before you take them out.

- Please open the vacuum package in a clean room when the products are to be applied.

- If the products are found damaged during courier, please take a picture or record a video immediately. DO NOT take the damaged products out of the packaging box! Contact us immediately and we will solve the problem well.